Key words: Graphite Electrodes, Refractory Material(brick, Mix), Copper Mould Tube, Mill Roll

+86 186 4091 3888

Key words: Graphite Electrodes, Refractory Material(brick, Mix), Copper Mould Tube, Mill Roll

+86 186 4091 3888

We specially in supplying Copper Mould Tube, Crystallizing equipment of continuous casters, Mould cooling jacket, Repair of copper moulds tube, etc. The precision engineering of our copper mould tubes guarantees the seamless operation of the continuous casting process, allowing for long-term, uninterrupted production.

Product Description

Copper Mould Tubes are the cornerstone of the Continuous Casting Machine, designed to provide the highest standards in the steelmaking industry. These copper mold tubes are meticulously crafted to ensure a uniform and strong billet shell upon exit, thereby preventing any casting accidents such as bursting or leakage.

Copper Mould Tubes Features

◆ Good Cooling Effect

Our high-quality copper mould tubes offer an exceptional cooling effect, which is crucial for forming a uniform and robust billet shell that can withstand the pressures of steel liquid and billet pulling forces.

◆ Enhanced Strength with Silver

The incorporation of approximately 0.1% silver into our raw materials significantly boosts the strength of the copper mould tubes without compromising their thermal conductivity.

◆ Precipitation Hardening

The use of Cr and Zr in our alloy provides the copper mould tube for ccm with high strength, excellent heat resistance, and thermal conductivity, ensuring they perform optimally under demanding conditions.

◆ Special Coatings

We employ hard chromium plating to extend the life of our copper mould tubes. We offer a range of coatings including Cr, Ni-Cr, Ni-Fe, and Ni-Cr to cater to the diverse needs of our domestic and international clientele.

We specially in supplying Copper Mould Tube, Crystallizing equipment of continuous casters, Mould cooling jacket, Repair of copper moulds tube, etc.

Equipments & Spare parts for Continuous Casting Machine.

1. Copper mould tube( square, rectangle and round )

2. Crystallizing equipment of continuous casters

3. Mould cooling jacket.

4. repair of copper tube moulds

COPPER MOULD ALLOYS

The copper alloys chosen for the moulds must maintain their physical properties at the operating temperatures of the continuous casting process.

The temperature gradation from the inner wall of the mould to the outside face of the mould can cause serious distortion problems, and it is imperative that the correct alloy is chosen for the various operating conditions.

STANDARD MATERIALS

Phosphorus de-oxidised copper

This alloy has been proven to be excellent for the manufacture of moulds in the continuous casting of billets. The main composition of this alloy are Cu +Ag 99.90min, P0.0015 / 0.040.

Copper -Silver alloy

The addition of a small amount of silver, whilst not increasing the melting point of copper, does increase the recrystallisation temperature by almost 100℃, and also helps to give better thermal conductivity at the operating temperatures.

This alloy is normally used in moulds for the continuous casting of blooms and slabs .In this case, the moulds are much thicker than in the billet moulds, and the moulds temperature can be higher. The main composition of this alloy are Cu+Ag99.90 min. Ag 0.08 / 0.12 O 0.004 / 0.012.

COPPER MOULD TUBE

The continuous casting of molten steel into billets, blooms and slab products, has been highly refined over the years into an extremely sophisticated system. The continuous casting process is expected to produce metallurgically sound products at the lower possible cost, and this is being achieved in many steelworks throughout the world.

Copper moulds have played an important role in the development of the continuous casting process. Their funcition is to receive the molten steel and to allow rapid heat transfer from the steel to the cooling water to enable quick solidification.

The mould must exhibit excellent thermal conductivity, be resistant for thermal erosion ,and be resistant to distortion from thermal stress. So far only copper and a few copper alloys meet the above conditions, both economically and technically.

SOLIDIFICATION

The rate of solidification in the continuous casting process dictates the speed of production. The molten steel, which is in contact with the inner faces of the copper mould, starts to sllidify as rapidly as the heat is extracted, forming a shell. The shell increases in thickness as more heat is extracted, and eventually total solidfication is achieved. the process is similar to the solidification of ingots in ingot moulds. In continuous casting, the whole process is speeded up, with the aim to produce and homogeneous shell growth. Consequently, the mould is an important part of the continuous casting process, and the manufactured quality of the mould plays and important role in their length of life.

INNER SURFACE COATINGS

Over the years, Metallurgists and Engineers have been working together to develop better continuous casting moulds. The steel companies require a more economical mould which will give a longer service life. Surface coating of the inner walls of the mould has given the best results to date. Coatings available are Chromium and Nickel plating. Also, a combination of the two give good results on slab casting.

SPECIFICATIONS OF COPPER MOULD

Square Copper mould tube

Square 60 x 60 - 350 x 350 (mm)

Rectangle 120 x 160 - 180 x 300 (mm)

Round Copper Mould tube

Diameter 100-400 (mm)

Size(mm): 90x90, 100x100, 110x110, 115x115, 120x120

130x130, 135x135, 140x140, 143x143, 150x150

155x155, 160x160, 165x165, 175x175, 180x180

200x200, 220x220, 100x170, 100x173, 130x240

150x200, 150x210, 150x220, 160x200, 160x220

150x225, 160x235, 165x225, 175x225, 180x220

200x240, 240x240, 235x235

Radius(mm): 4000, 5000, 5250, 6000, 7000, 7500, 8000, 9000, 10250, 10300, 11000, 12000

Length(mm): 700, 750, 780, 790, 800, 810, 812, 850, 900, 1000

Company Service

◆ Customized Design: Our copper mould tubes are designed according to your specific industrial needs, helping to reduce costs and enhance efficiency.

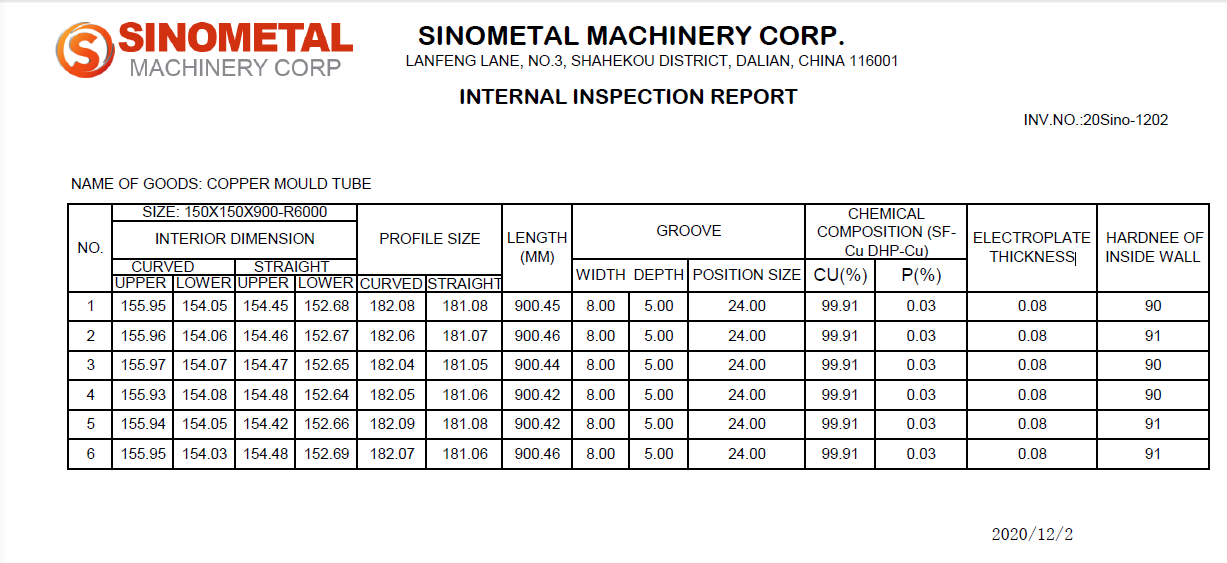

◆ High-Quality Standards: All our products meet ISO9001 standards, ensuring high precision, the correct hardness requirement, perfect taper, and a well-applied coated layer.

◆ Complete Processing Facilities: We have the necessary infrastructure to process every copper mould tube, including galvanizing plating and hardness testing.

◆ Prompt Delivery: As a professional copper mould tube manufacturer, Sinometal Carbon is committed to supplying our high-quality and durable copper mould tubes at the most competitive prices with prompt delivery to meet your production timelines.

Navigation

Tel:: +86 186 4091 3888

Fax: +86 411 3962 5877

Mobile: +86 186 4091 3888

E-mail: jack@sncarbon.cn

QQ: 695993847

Address: Zhongshan District, Dalian City,116001. China.